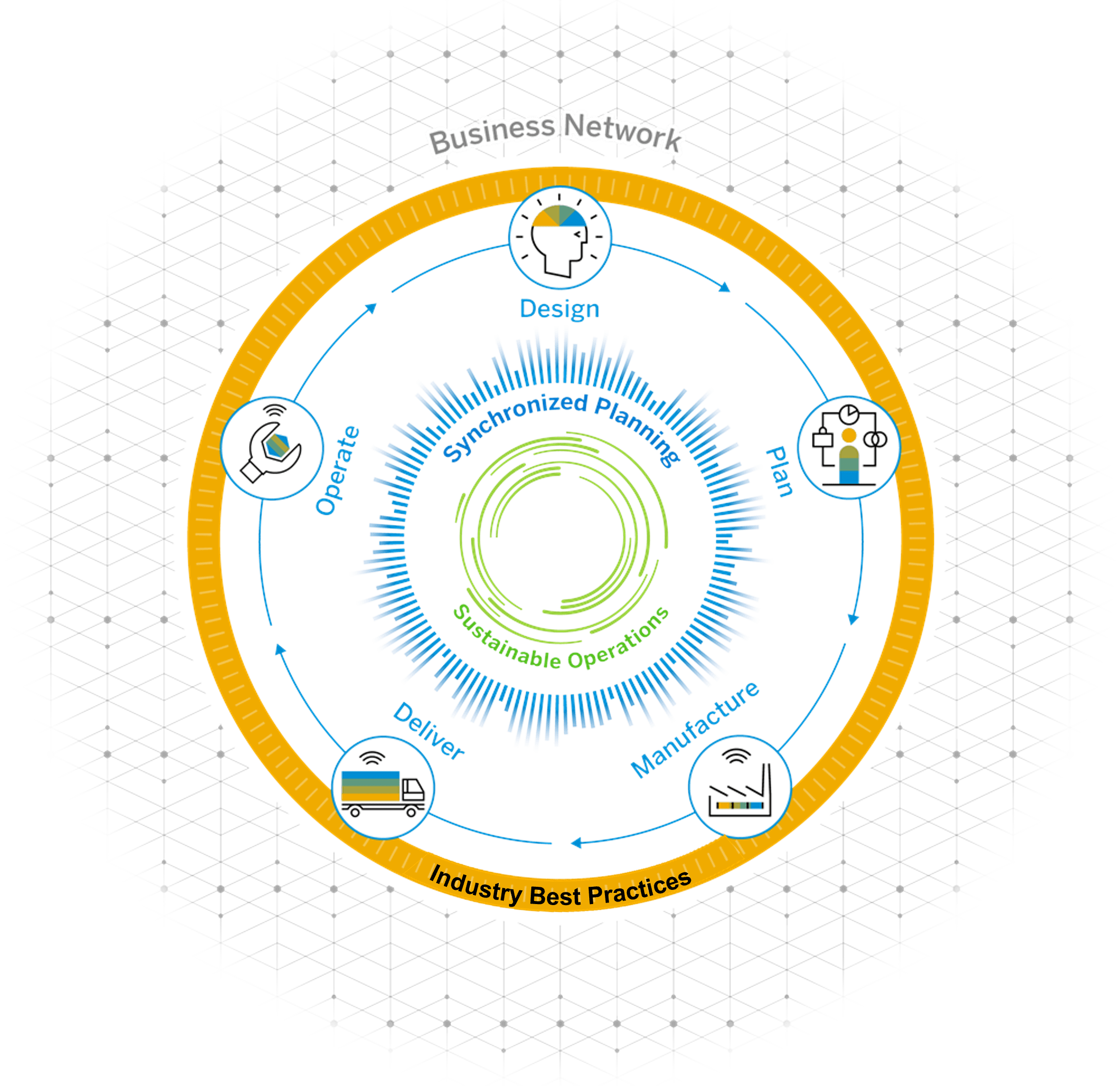

Build the next Generation Resilient Supply Chain Solution

SAP Digital Supply Chain revolutionizes traditional manufacturing processes by leveraging Industry 4.0 principles and advanced technologies like IoT, AI, ML, and predictive analytics. This comprehensive suite empowers manufacturers to establish smart, interconnected, and adaptable production environments. With real-time insights into machine performance, production quality, and supply chain dynamics, businesses can optimize efficiency, minimize downtime, reduce waste, and ensure consistent product quality. By promoting paperless production, intuitive interfaces, automated data collection, and dynamic control of shop floor activities, SAP Digital Supply Chain fosters cost reduction, increased productivity, and enhanced quality. Solution ensures optimal operations and responsiveness to short-term changes through Shift and labor planning, alongside production order scheduling while considering labor, resource, and maintenance constraints. Solution enables

Shift and Labor planning

Optimal shift and labor planning ensures business operations run smoothly with the right skill sets, maximizing productivity and efficiency.

Production scheduling & dispatching

Optimally plan operations and adopt to short term changes considering labor, resource and maintenance constraints.

Cross plant real-time analytics

For manufacturing performance e.g. perfect order fulfillment, Overall Equipment Effectiveness, loss analysis along with machine data to identify improvement opportunities.

Customers desire a Resilient Supply Chains from Design to Operate because of the following reasons

Sense, predict, and respond to insulate from disruption.

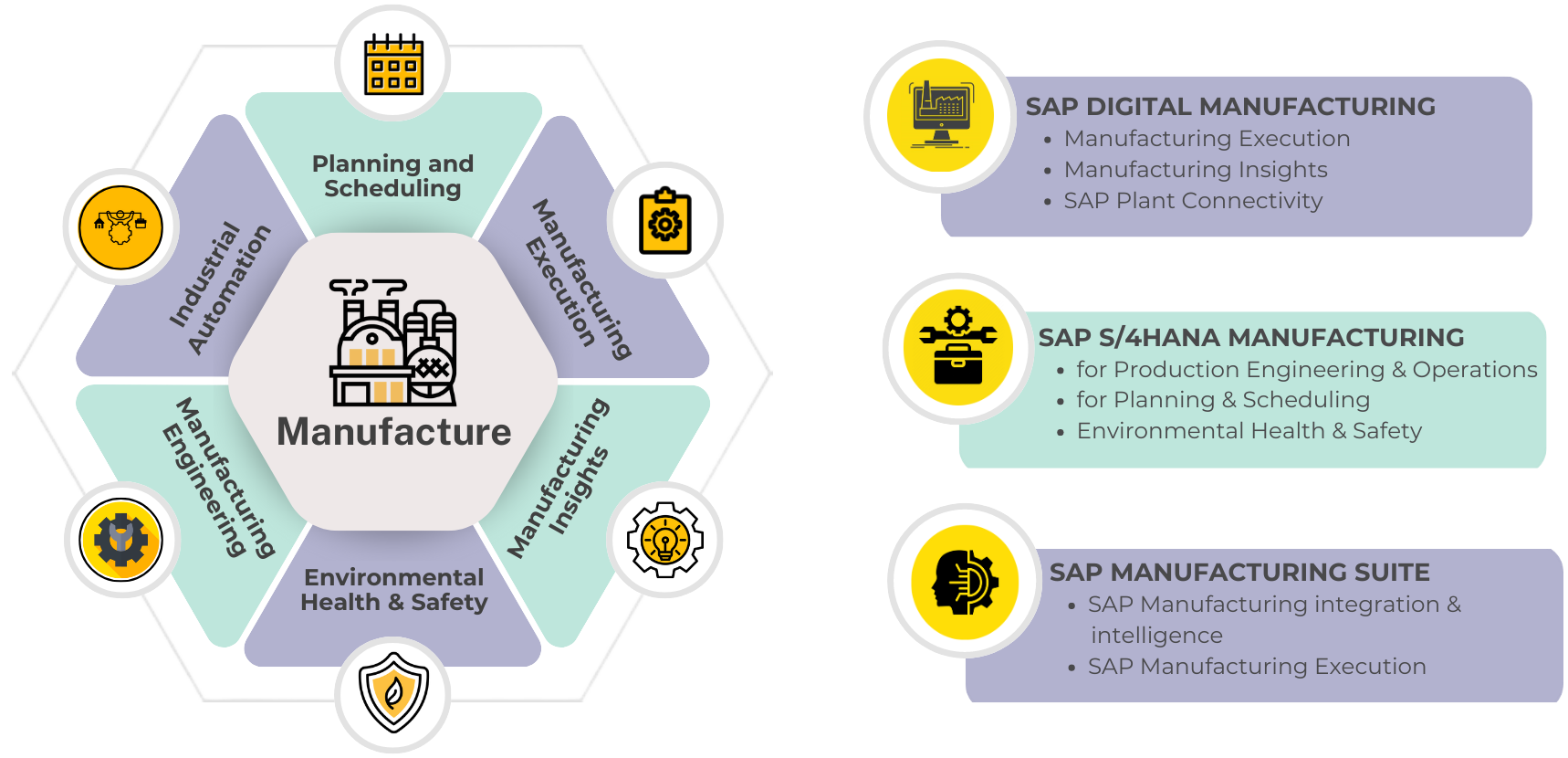

SAP delivers a complete portfolio of digital manufacturing solutions

Use relevant SAP digital manufacturing solutions to analyze & optimize your digital operations

- Self-service manufacturing analytics with harmonized access for better visibility and extensibilit

- Live Production monitoring along the plant hierarchy and across multiple dimensions in real-time

- Operational analytics using KPIs & dashboards to drive data-driven decisions

- pre-delivered advanced analytics to increase productivity, quality and sustainability

- Closed-loop analytics to trigger actions fueling a continuous improvement process

Ready To Transform your Business?

Ensuring seamless Integration and enhanced Operational Efficiency for your business

Book a Free Consultation

.jpg)